Authors:

Subbiah Seenivasan1*, Kirubakaran Dhanakodi2 and Narayanan Nair Muraleedharan3

1The Institute of Environmental and Human Health, Texas Tech University, Lubbock – 79415, Texas, USA

2UPASI Tea Research Foundation, Nirar Dam BPO, Valparai – 642 127, India

3Tea Research Tea Research Association, Tocklai Experimental Station, Jorhat-78500, Assam, India

Received: 04 September, 2015; Accepted: 12 October, 2015; Published: 14 October, 2015

S. Seenivasan, The Institute of Environmental and Human Health, Texas Tech University, Lubbock – 79415, Texas, USA, Tel: +001-806-885-4567; Fax: +001; E-mail:

Seenivasan S, Dhanakodi K, Muraleedharan NN (2015) Residues of Propargite in Tea. Int J Agricultural Sci Food Technology 1(1): 012-015. DOI: 10.17352/2455-815X.000004

© 2015 Seenivasan S, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Propargite; Residues; Tea; Persistence; Dissipation; MRL

Propargite is an acaricide extensively used in India for controlling the populations of the red spider mite (RSM) infesting tea. Field experiments were conducted at two places in Tamil Nadu (India) during the dry season to determine the residues of propargite in black tea. Residues were quantified at different harvest intervals of '0' (3 hr), 1st, 3rd, 5th, 7th, 10th and 14th day after acaricide application. Persistence, dissipation pattern, half-life value and safe harvest interval of the acaricide in tea were calculated. Residues of propargite dissipated exponentially after application at both the locations and reached below the CODEX MRL of 5 mg/kg on the 7th day. Regression lines drawn on propargite showed that like other acaricides it followed the first order dissipation kinetics. Half-life values varied from 1.63 to 1.92 days for propargite and a safety harvest interval of 7 days is suggested for the tea crop.

Introduction

Tea contains an array of chemical constituents, some of which are as unique as the plant itself. The main constituents of tea leaves are carbohydrates, proteins, polyphenols, caffeine, theanine, enzymes, vitamins and minerals. The chemicals in the green tea leaves undergo drastic changes when they are processed into black, green or oolong tea. From the pharmacological and therapeutical points of view polyphenols and caffeine are the most important, though vitamins and minerals are also considered medically significant research has indicated that the beneficial effects of tea are due its polyphenolic contents that may affect carcinogen metabolism, free radical scavenging and formation of DNA adducts [11. Chung S. Yang, Hong Lu, Xiaofeng Meng, Jie Liao, Guang-yu yang, et al. (2001) Bioavailability and biological activity of tea polyphenols, Proceedings of 2001 International Conference on O-CHA (tea) culture and science, Shizuoka Japan 30-33.,22. Zhang H, Spitz MR, Tomlinson GE, Schabath MB, Minna JD, et al. (2002) Modification of lung cancer susceptibility by green tea extract as measured by comet assay, Cancer Detect Prev 26: 411-418.]. Such a healthy beverage should also be free from the residues of pesticides and heavy metals. The tea crop is attacked by several pests and diseases and it is imperative that plant protection chemicals are applied to reduce the severity of infestation.

Propargite (Omite 57 EC) [2-(p-tert-butylphenoxy)cyclohexyl 2-propynyl sulfite] an acaricide with a unique chemical configuration consisting sulfite moiety, has found a place in the list of chemicals recommended for red spider mite control in tea in south India [33. Muraleedharan N, Hudson JB, Durairaj J (2007) Guidelines on tea culture in south India (18th ed.) Coonoor, India: United Planters' Association of Southern India.]. Propargite is registered with Central Insecticides Board (CIB) in India for usage on tea and cleared under the Prevention of Food adulteration (PFA) Act. A few reports are available on the degradation of certain commonly used pesticides and their residues in tea [44. Rajukkannu K, Blasubramanian M, Vasudevan P (1981) Residues of dicofol and tetradifon in tea leaves. J Plantn Crops 9: 124-125.-1010. Sood C, Jaggi S, Kumar V, Ravindranath SD, Shanker A (2004) How manufacturing processes affect the level of pesticide residues in tea. J Sci Food Agric 84: 2123–2127.]. Similarly research papers have been published on the residues of propargite in tomatoes [1111. Sarlis AP, Liapis KS, Miliadis GE (1994) Study of procymidone and propargite residue levels resulting from application to greenhouse tomatoes. J Agric Food Chem 42: 1575-1577.], fruits and vegetables [1212. Yu L, Schoen R, Dunkin A, Firman M, Cushman H, Fontanilla A (1997) Determination of o-phenylphenol, diphenylamine, and propargite pesticide residues in selected fruits and vegetables by gas chromatography/mass spectrometry. J AOAC Internl 80: 651-656. ] and dissipation behavior of propargite residues in soil, apple and tea [1313. Kumar V, Sood C, Jaggi S, Ravindranath SD, Bhardwaj, Shanker A (2005) Dissipation behavior of propargite-an acaricide residues in soil, apple (Malus pumila) and tea (Camellia sinensis). Chemos 58: 837-843.]. However, there is no published information on the residues of propargite in black tea under the agro climatic conditions of south India. Hence, a study was undertaken to generate data on residues, persistence and dissipation of propargite in tea.

Materials and Methods

Field trials and experimental design

The experiments were conducted in tea fields at Valparai and Coonoor (Tamil Nadu, India). Plots measuring 100 sq.m, containing tea plants of mixed cultivars with appropriate guard rows, were used for the study. Tea plants had been planted in double hedge, in triangular planting system at a spacing of 0.75 x 0.75 x 1.25 m under the shade tree, Grevillea robusta (6 x 6 m spacing).

The treatments were application of propargite 57 EC @ 1000 and 2000 mL/ha and an untreated control. The acaricide was applied with hand operated knapsack sprayer, using a spray volume of 400 L/ha. Tea shoots consisting of three leaves and a bud were harvested on 0 (3 hours), 1st, 3rd, 5th, 7th, 10th and 14th days after application of the chemical. The shoots harvested on the specific day after chemical application were processed in a miniature manufacturing unit. Harvested shoots were spread in a withering trough and allowed to wither with natural air, blown underneath for 16-18 hours. Withered leaves were passed through a rotorvane for crushing and mixing of leaves and juice. This was passed four times through a roller cut CTC (Crush, Tear and Curl) machine. The resulting cut “dhool” was spread over the fermentation trays at a thickness of about 2 cm, maintaining a relative humidity of 90-95% for one hour. Fermented (enzymic oxidation) “dhool” was dried in a mini fluid bed drier to attain a final moisture content of 2.5-3.0%. Black tea samples thus obtained were analysed in a high performance liquid chromatograph (HPLC, Agilent 1100 Series) equipped with diode array detector, following standard procedure.

Chemicals and reagents

An analytical reference standard of propargite (purity 95.40 %) was procured from Dr. Ehrenstorfer, Germany and the commercial formulation of propargite (Omite 57E) was supplied by the manufacturer, M/s. Chemtura Chemicals Pvt. Limited, Mumbai, India. Hexane, acetone, isopropyl alcohol, sodium chloride and sodium sulphate were obtained from M/s. Merck, Mumbai, India; all were of chromatographic purity. Florisil (60 – 100 mesh, pesticide residue grade) was obtained from M/s. Sigma – Aldrich fine chemicals, Bangalore, India.

Instrument and calibration

Details of the instruments employed and the conditions of operations for analysis of residues of propargite are given below. An Agilent 1100 Series HPLC with a diode array detector was used for separation and quantitative analysis, and a Zorbax Rx C18 column (25 cm length, 4.6 mm internal diameter and 5µm film thickness) was used for HPLC determination. Acetonitrile and water (75:25, v/v) at a flow rate of 1.50 ml/min was used as the mobile phase. The temperature of oven was set at 40°C and 10 µL of sample was injected for detection. Quantification was accomplished by using a standard curve prepared by diluting the stock solution in acetonitrile. Good linearity was achieved in the range 0.10 – 5.0 µg/mL with a correlation coefficient of 0.9996. The limit of detection was estimated to be 0.1 µg/mL of propargite. The column was conditioned by three repeated injections of standard and sample extracts until HPLC peaks were reproducible.

Analysis

Extraction: Ten gram of black tea sample was hydrated with 5 mL of double distilled water and extracted 3 times with 100 mL mixture of 1:1 isopropyl alcohol: hexane by shaking it in a mechanical shaker for two hours. The contents are filtered, washed with 80 mL of isopropyl alcohol: hexane and the extract was transferred to 500 mL separating funnel for partitioning.

Clean up: To the filtrate, 125 mL of saturated sodium chloride solution was added and shaken vigorously. After allowing the layer to separate, hexane layer was allowed to pass through the anhydrous sodium sulphate placed in the funnel. The aqueous extract was again partitioned twice with 50 mL of hexane and collected hexane layer passed through anhydrous sodium sulphate layer. The aqueous layer was discarded. The hexane extract was concentrated in a rotary vacuum evaporator with a water bath maintained at 60°C. The concentrated residue was dissolved in hexane and transferred to a glass column packed with cent per cent activated florisil (10g) with 1 cm layer of anhydrous sodium sulphate in top and bottom of florisil. Prior to the elution, the column was washed with 50 mL of hexane to remove the co-extractives and the washings were discarded. The compound was eluted with 75 mL of 5 per cent acetone in hexane. After evaporation, the samples were diluted to 10 mL with acetonitrile (HPLC grade) and analyzed in HPLC [1414. Selvasundaram R (2002) Entomology. Annual Report of UPASI Tea Research Institute, Nirar Dam BPO, Valparai – 642 127, Coimbatore District, India 31-32.].

Propargite residues in tea brew: About 2g of made tea was infused in 100 mL of boiling water (ISO 3103 -1990). After 6 minutes of brewing, the water extract was filtered, cooled and partitioned with 100 mL of hexane. The organic phase was passed through anhydrous sodium sulfate. The extract was concentrated by evaporating in a rotary vacuum evaporator and diluted with 10 mL hexane and analyzed for the residues of propargite. The spent leaves were dried between the folds of filter paper and residues were extracted following the method described above for black tea.

Results and Discussion

Recovery of propargite from black tea

The analytical method was validated for black tea prior to actual analysis. To validate the analytical method, recovery percentage was established by fortification of technical standard solutions of propargite from untreated control black tea. For determination of recovery percent of propargite from black tea samples, 10 g of control tea sample was fortified with 1.0024 mg/kg of propargite, replicated three times. After mixing and allowing the solvent to evaporate, the samples were analyzed for the concentration of propargite residues as described earlier. The recovery achieved was 98.10% at 1.0024 mg/kg level of fortification for black tea, which was a clear validation of the procedure adopted for extraction and analysis of propargite residues from tea samples. Recoveries of the pesticide at different fortification levels, i.e. 0.5, 1 and 5 µg/mL were determined in six replicates from each matrix to validate different analysts and evaluate the accuracy of the method.

Kinetics of dissipation

The residue data were subjected to simple regression analysis. From the regression equation, half-life and safety harvest (i.e. minimum number of days to elapse for the residues to reach tolerance limit) were calculated as suggested by Regupathy and Dhamu [1515. Regupathy A, Dhamu K (1990) Statistical work book for insecticide toxicology. Soorya Desk Top Publishers 1-177.].

Propargite residues in black tea

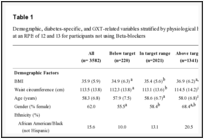

The residues of propargite in black tea when applied @ 1000 and 2000 mL/ha during dry season at different harvest intervals are given in the Table 1. Propargite residues present in the processed black teas dissipated gradually and were low as 3.40 mg/kg and mg/kg at Valparai and Coonoor respectively on the 7th day after spraying and subsequently propargite residues were not detectable in tea. When applied at high dosage residues were 5.11 mg/kg and 5.07 mg/kg. Based on the above data, half-life, the pre-harvest interval (PHI) after application of propargite in tea was calculated. Regression lines drawn on propargite showed that it followed the first order dissipation kinetics (Table 2). Studies on the infusion indicated that propargite residues did not leach into the tea brew (Table 3).

-

Table 2:

Kinetics of dissipation of propargite in black tea at Valparai and Coonoor.

-

Table 3:

Kinetics of dissipation of propargite in black tea at Valparai and Coonoor.

Pihlstrom et al. [1616. Pihlström T, Blomkvist G, Friman P, Pagard U, Österdahl BG (20070 Analysis of pesticide residues in fruit and vegetables with ethyl acetate extraction using gas and liquid chromatography with tandem mass spectrometric detection. Anal Bioanal Chem 389: 1773–1789.], reported the analysis of pesticide residues including propargite in fruit and vegetables with ethyl acetate extraction using gas and liquid chromatography with tandem mass spectrometric detection. Further, they proposed that the multi-residue method was simple, straightforward, without cleanup, and made it possible to extract, determine and confirm roughly 300 analytes in one single analysis using LC-MS/MS and GC-MS/MS. Kumar et al. [1313. Kumar V, Sood C, Jaggi S, Ravindranath SD, Bhardwaj, Shanker A (2005) Dissipation behavior of propargite-an acaricide residues in soil, apple (Malus pumila) and tea (Camellia sinensis). Chemos 58: 837-843.], investigated the dissipation behaviour of propargite in soil and plant material. They also reported that the MRL in apple fruits were below the prescribed guidelines after 9 days of the treatment, while in tea, residue levels were below the MRL, 7 days after treatment. Data are also available on the potentiation of propargite and fenpyroximate mixture against two-spotted spider mite, Tetranychus urticae [1717. Herron GA, Rophail J, Holloway J, Barchia I (2003). Potentiation of a propargite and fenpyroximate mixture against two-spotted spider mite, Tetranychus urticae (Acari: Tetranychidae). Experimentl Appl Acarol 29: 115–119.]. In tea fields, besides the effects of some physical and chemical factors like light, temperature, pH, moisture, degradation of insecticides, growth dilution might have also played significant role and rendered propargite residue unavailable in short a period. Growth dilution is an important factor in reducing the residue levels in tea crop as the shoots on which pesticides are applied, are in different stages of growth [1818. Agnihothrudu V, Muraleedharan N (1990) Pesticide residues in tea. Planters' Chronicle 85: 125-127.-2020. Chen ZM, Wan H (1988) Factors affecting residues of pesticides in Tea. Pestic Sci 23: 109-118.]. Withering of tea leaves was a major reason for total degradation. This might be due to evaporation during withering process. Chen and Wan [2020. Chen ZM, Wan H (1988) Factors affecting residues of pesticides in Tea. Pestic Sci 23: 109-118.] reported 30 to 60 per cent of reduction in pesticide residues during processing, especially during drying.

Transfer of residue from manufactured tea to infusion and spent leaves

The quantity of propargite residues transferred from processed black tea to infusion was not detectable. While the residues remained in the spent leaves, the infusion was almost free from propargite, when applied at the recommended rate of 1000 mL/ha. Generally, only those pesticides with high water solubility are potentially transferred to the tea cup, in significant amounts. The rate of transfer of the pesticide residues to the infusion depends on its solubility in water [2121. Nagayama T, Maki T, Kan K, Iida M, Tamura Y, et al. (1996) Residues of organophosphorus pesticides in commercial tea and their leaching into tea. Nippon Noyaku Gakkaishi 14: 39-45.] and partition coefficient [2222. Jaggi S, Sood C, Kumar V, Ravindranath SD, Shanker A (2001) Leaching of pesticides in tea brew. J Agric Food Chem 49: 5479-5483.]. Propargite with very low water solubility (0.215 mg/L) and low octanol-water coefficient (Kow 5,01,187) supported the findings [2323. The Pesticide Manual (2003) 8th ed. UK: British Crop Protection Council.].

Conclusion

CODEX of FAO/WHO has regulated an MRL of 5 mg/kg for propargite in tea. It is evident that black tea processed from green shoots collected after 7-10 days, after spraying at recommended dose had residues below MRL. The waiting period based on MRL in black tea may be therefore fixed as 7 days for propargite. Thus, the consumption of tea infusion is safe, when the leaves are processed after the normal harvesting interval, after the spraying of propargite. Thus the present findings are useful in monitoring the residues of propargite in tea.

Acknowledgements

The authors are grateful to the National Tea Research Foundation (NTRF), C/o. Tea Board, Govt. of India for the financial assistance for this work. The authors gratefully acknowledge M/s. Chemtura Chemical India Pvt. Limited, Mumbai for his guidance and suggestions for this study.

- Chung S. Yang, Hong Lu, Xiaofeng Meng, Jie Liao, Guang-yu yang, et al. (2001) Bioavailability and biological activity of tea polyphenols, Proceedings of 2001 International Conference on O-CHA (tea) culture and science, Shizuoka Japan 30-33.

- Zhang H, Spitz MR, Tomlinson GE, Schabath MB, Minna JD, et al. (2002) Modification of lung cancer susceptibility by green tea extract as measured by comet assay, Cancer Detect Prev 26: 411-418.

- Muraleedharan N, Hudson JB, Durairaj J (2007) Guidelines on tea culture in south India (18th ed.) Coonoor, India: United Planters' Association of Southern India.

- Rajukkannu K, Blasubramanian M, Vasudevan P (1981) Residues of dicofol and tetradifon in tea leaves. J Plantn Crops 9: 124-125.

- Singh RP, Agnihotri NP (1984) Residues of dicofol, endosulfan and Malathion on tea. Camellia sinensis (L) O. Kuntz J ENT Res 8:14-16.

- Manikandan KN, Muraleedharan N, Selvasundaram R (2001) Residues of deltamethrin in black CTC tea. Bulletin of UPASI Tea Research Foundation. 54: 88-92.

- Manikandan KN, Muraleedharan N, Selvasundaram R (2005) Degradation of quinalphos during the processing of black CTC tea. J Plantn Crops 33: 146-148.

- Manikandan KN, Smitha S, Seenivasan S, Muraleedharan N, Selvasundaram R (2006) Fenazaquin residues in tea and its persistence in south Indian climatic conditions. J Plantn Crops 34: 410-413.

- Kumar V, Tewary DK, Ravindranath SD, Shanker A (2004) Investigation in tea on fate of fenazaquin residue and its transfer in brew. Food Chem Toxicol 42: 423–428.

- Sood C, Jaggi S, Kumar V, Ravindranath SD, Shanker A (2004) How manufacturing processes affect the level of pesticide residues in tea. J Sci Food Agric 84: 2123–2127.

- Sarlis AP, Liapis KS, Miliadis GE (1994) Study of procymidone and propargite residue levels resulting from application to greenhouse tomatoes. J Agric Food Chem 42: 1575-1577.

- Yu L, Schoen R, Dunkin A, Firman M, Cushman H, Fontanilla A (1997) Determination of o-phenylphenol, diphenylamine, and propargite pesticide residues in selected fruits and vegetables by gas chromatography/mass spectrometry. J AOAC Internl 80: 651-656.

- Kumar V, Sood C, Jaggi S, Ravindranath SD, Bhardwaj, Shanker A (2005) Dissipation behavior of propargite-an acaricide residues in soil, apple (Malus pumila) and tea (Camellia sinensis). Chemos 58: 837-843.

- Selvasundaram R (2002) Entomology. Annual Report of UPASI Tea Research Institute, Nirar Dam BPO, Valparai – 642 127, Coimbatore District, India 31-32.

- Regupathy A, Dhamu K (1990) Statistical work book for insecticide toxicology. Soorya Desk Top Publishers 1-177.

- Pihlström T, Blomkvist G, Friman P, Pagard U, Österdahl BG (20070 Analysis of pesticide residues in fruit and vegetables with ethyl acetate extraction using gas and liquid chromatography with tandem mass spectrometric detection. Anal Bioanal Chem 389: 1773–1789.

- Herron GA, Rophail J, Holloway J, Barchia I (2003). Potentiation of a propargite and fenpyroximate mixture against two-spotted spider mite, Tetranychus urticae (Acari: Tetranychidae). Experimentl Appl Acarol 29: 115–119.

- Agnihothrudu V, Muraleedharan N (1990) Pesticide residues in tea. Planters' Chronicle 85: 125-127.

- Bisen JS, Ghosh Hajra N (2000) Residues and persistence of certain insecticides in Darjeeling tea. J Plantn Crops 28: 123-131.

- Chen ZM, Wan H (1988) Factors affecting residues of pesticides in Tea. Pestic Sci 23: 109-118.

- Nagayama T, Maki T, Kan K, Iida M, Tamura Y, et al. (1996) Residues of organophosphorus pesticides in commercial tea and their leaching into tea. Nippon Noyaku Gakkaishi 14: 39-45.

- Jaggi S, Sood C, Kumar V, Ravindranath SD, Shanker A (2001) Leaching of pesticides in tea brew. J Agric Food Chem 49: 5479-5483.

- The Pesticide Manual (2003) 8th ed. UK: British Crop Protection Council.

Table 1:

Residues of propargite in black tea at Valparai (V) and Coonoor (C)..

ND: non detectable; BDL : below the detection limit.