Authors:

Ogori Akama Friday1*, FF Ajayi1, OA Folorunsho2 and AF Ogori1

1Department of Home Science, Federal University Gashua, P.M.B. 1005, Yobe State

2Department of Home Science, Nasarawa State University, Keffi, Nasarawa State

Received: 01 June, 2017; Accepted: 24 July, 2017; Published: 26 July, 2017

Ogori Akama Friday, Department of Home Science, Federal University Gashua, P.M.B. 1005, Yobe State, E-mail:

Friday OA, Ajayi FF, Folorunsho OA, Ogori AF (2017) Quality Characteristics of shortbread Biscuit Fortified with Fermented Jack bean Flour. Int J Agric Sc Food Technol 3(3): 036-041. DOI: 10.17352/2455-815X.000020

© 2017 Friday OA, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Biscuit are usually produced from wheat flour, increasing cost and limited supply of wheat demand that attention be given to the application of indigenous grains to totally or partially replace wheat in bakery products. This study evaluated the effect of substituted fermented jack bean flour (FJF) on wheat flour on proximate, mineral, physical and sensory properties of shortbread biscuit (SBB). Jack beans were soaked in water (6 h), de-hulled, re-soaked (12 h), sundried (3 days), oven-dried (55 °C, 24 h), milled, sieved and packaged for further processing. Shortbread biscuits (SBB) were produced using different levels of wheat flour substituted with FJF in 10% and 20% and using wheat flour as control. Sensory evaluation of the biscuits was carried out using 5 point hedonic scale. The data obtained during the study was analyzed statistically using analysis of variance. Proximate composition, mineral, physical characteristics and sensory properties of the biscuit samples were determined. Moisture, crude protein, crude fibre, fat, ash and carbohydrate of the SBB ranged from 6.85-8.77, 8.41-10.17, 1.58-2.14, 18.39-19.42, 1.81-2.11 and 59.49-61.51%, respectively. Addition of FJF significantly increased the Ca (0.11 %), P (6.38 %), Mg (0.18 %), Fe (2.29 %) and Mg (2.18 %) of the SBB compared to values obtained from 100% wheat flour. SBB with 20% FJF had the highest spread factor and spread ratio of 5.73 and 6.62, while SBB with 10% FJF had the least value. Sensory evaluation showed that SBB with 10 % FJF was preferred in terms of flavour, mouth feel and overall acceptability. It was concluded that substitution of FJF into wheat flour gave the biscuit with the best overall quality acceptability

Introduction

The bakery industry is growing very fast and the products are increasingly becoming popular among all sections of people. Among ready-to-eat snacks, biscuits possess several attractive features including wider consumption base, relatively long shelf-life, more convenience and good eating quality [1,2]. They are traditionally made from soft wheat, a cereal, which is cultivated in many parts of the world, but imported by countries with unfavorable climatic conditions. Such importing countries spend a lot of foreign exchange on importation of wheat. There is a compelling need to develop an adequate substitute for wheat, as the demand and price of this product could further be increased by natural disasters such as hurricanes, which destroy wheat crops and also the fact that many farmers are beginning to switch from growing wheat to growing “more lucrative” crops (like corn and soy beans), which could be used in the production of biofuels. In the quest for a wheat substitute, flour with better nutritional quality than wheat would be highly desirable, especially in developing countries where malnutrition is prevalent [3]. Composite flour bakery products have manifold advantages, apart from extending the availability of wheat flours; these are looked upon as carrier of useful functional food components and nutrients [4].

Jack bean (Canavalia ensiformis) is one of the under exploited tropical dry beans. It is usually used in Nigeria as an ornamental plants, grown near houses and allowed to trail on walls and trees [5]. It is, however, fairly widely distributed, being cultivated in Africa, Asia, the West Indies, Latin America and India. The jack bean can be grown in marginal soils and arid to semi-arid regions not suitable for common legumes such as Phaseolus and Vigna species. It has, therefore, great potential in most tropical and subtropical parts of the world [6]. The seed of jack bean, the highly produced large seeded tropical legume, contains about 300 g/kg crude proteins and 600 g/kg carbohydrates [7]. Canavalia ensiformis ranks among the underutilized legumes that could ameliorate protein deficiency in human nutrition, particularly in developing countries.

Processing techniques such as germination and fermentation have been found to improve the quality of cereals and legumes due to chemical changes that enhance contents of free sugars, protein and vitamins, as well as bioavailability of minerals [8,9,10], reported that germination induces an increase in free limiting amino acids with modified functional properties of seed components [11], have also reported that fermentation of grains improves amino acid composition and vitamin content, increases protein and starch availabilities and lowers levels of anti-nutrients. It is therefore expected that composite flour produced from germinated cereals and fermented legumes will have the advantage of improving overall nutrition.

As there is a growing interest in the production of baked products, biscuit are usually produced from 100% wheat flour which do not contain the required balance essential amino acid for human. There is need to fortify wheat flour with the readily available jack bean seed flour for high nutrient and higher quality product. This study was undertaken to produce short-bread biscuit of acceptable quality from fermented jack bean flour and wheat flour blends without affecting its sensory attributes. Thus, the objective of this study was to produce shortbread biscuit fortified with fermented jack bean seed flour and to evaluate its physicochemical and sensory properties.

Materials and Methods

Materials

Jackbean (Canavalia ensiformis) seeds of white variety were purchased from retail stocker at Alamis market in Lafia, Nasarawa State, Nigeria. Wheat flour (Triticum aesticum), sugar, baking powder, vanilla essence, common salt, margarine, nut meg and rice flour were purchased from a commercial stocker in Lafia main maket, Nasarawa state, Nigeria. All laboratory reagents used for the analysis in this work were all of analytical quality.

Processing of jackbean seeds into fermented jack bean flour

The processing of Jack bean seeds was done using spontaneous fermentation. This semi-solid state fermentation involves washing and removing stones, dirt, and other debris from the beans. The jackbean was weighed, soaked in excess cold water for six (6) hours to soften the seed coats and leach out colouring matter and substances that impact beany flavour in the flour, and dehulled manually and it as re-soaked in cold water for twelve (12) hours for fermentation take place and washed severally in clean water, sun dried for three (3) days and oven-dried (55 0C) for 72 hours to take care of any surface spoilage micro-organism adhesion. Then milled into fine flour and stored in polythene bag.

Preparation of shortbread biscuit

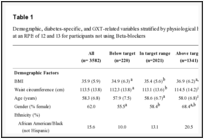

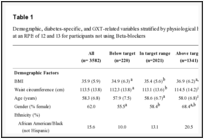

Samples of shortbread biscuits were prepared by first blending each of the flour blends in table 1, with other ingredient which include caster sugar (250g), margarine (375g), baking powder (2g), table salt (5g), rice flour (137g) vanilla essence and nut meg (1 whole seed) and then formed into barters of 4mm×5mm×2mm in shape. These were proofed for 10 mins and baked at oven temperature of 180 0C for about 1 hour. After baking, biscuit were exposed to cool in tray for 4 hours and then packed in polythene bags and stored in dry container for nutrient analysis and sensory evaluation.

Sample analysis

Flour and biscuit: Moisture was determined by hot- air oven drying at 1050C to constant weight [12]. Ash, protein (microKjeldahl, N × 6.25), crude fiber and fat (Solvent extraction) were determined by the [12], methods. Calorie was calculated using Atwater factors of 4 × % Protein, 4 × % carbohydrate and 9 × % fat and then taking the sum. Magnesium and Zinc were determined by flame photometry using a flame photometer as described by the [12], methods. Phosphorous was determined by the molybdovanadate method [12]. Calcium and Iron was determined using atomic absorption spectrophotometer [12].

Determination of physical analysis of biscuit

Cookies diameter and thickness were determined using vernier callipers, while cookies weight was determined using an electronic weighing balance. Spread ratio was expressed as diameter/thickness [13].

Sensory analysis

The samples were evaluated by thirty (30) panelists. The panelist were instructed to evaluate the organoleptic quality (i.e. color, texture, flavor, mouth feel and overall acceptability) using a five-point hedonic scale where five represents like extremely and one represent dislike extremely. Consumer testing was conducted at the home economics sensory analysis laboratory. The products were served to each panelist in similar sample retaining plate. The panelist were instructed to rinse their mouth with warm water which was provided to each of them before and after testing a product to avoid carry over effect.

Experimental design

The experimental design used was a completely randomized design (CRD) model with factorial experiment

Statistical analysis

Data obtained for proximate, mineral, physical properties and sensory analysis of biscuit sample was statistically analyzed using analysis of variance (ANOVA) of SPSS version 16. Least significant difference (LSD) test was used to estimate the significant differences among the means at 95% confidence level.

Results and Discussion

The results obtained from the proximate analysis of wheat flour, defatted jack bean flour and un-defatted jack bean flour are shown in table 2. The increased supplementation of whole wheat flour with jack-bean flour greatly affected the proximate composition of the blend. The proximate values for moisture, ash, fat and crude protein were lowest in whole wheat flour which served as control and higher in defatted and un-defatted jack bean flour samples. The moisture content of un-defatted (6.39 %) and defatted jack bean flour (6.71 %) was low suggesting that the seed might be able to withstand long period of storage and transportation. The carbohydrate content was highest in wheat flour (72.30 %) and lowest in un-defatted jack bean flour (55.07 %), respectively. The low carbohydrate content was as result of the low fat content of un-defatted jack bean flour. Similar trends were reported by [14,15], in the fortification of wheat flours with defatted and non-defatted soy flour, respectively.

-

Table 2:

Proximate composition of wheat flour, defatted jackbean flour, un-defatted jackbean flour.

The crude protein content of un-defatted jack bean flour was found to be higher than that of wheat flour. The crude protein content of un-defatted jack bean seeds (29.24 %) was found to be comparable with that of earlier reports on the same Jack bean (29.8 %) by [16]. According to [17], higher level of protein content of seed materials of Canavalia ensiformis has nutritional significance, since moderate intake of these seeds will greatly increase the total dietary protein intake of the consumers.

Fibre helps in the maintenance of human health and has been known to reduce cholesterol level in the body. The value obtained for crude fibre of un-defatted (2.21 %) and de-fatted bean seeds (2.22 %) was close with the value obtained for raw jack bean seed 2.55 % [23], but lower than the value reported earlier on jack bean (4.71-11.4%) by [18].

The fat content value of un-defatted (1.84 %) and defatted (1.36 %) jack bean flour were found to be lower than Cassia floribunda (2.1-3.1%) reported by [19], Canavalia gladiata (2.46%) [20], and Canavalia gladiata (2.8-3.8%) [21]. The ash content gives an idea of the amount of inorganic content of the sample from where the mineral contents could be obtained. However, the value obtained for ash content of un-defatted jack bean flour (5.24 %) was similar to the findings 5.80% reported for Cajanus cajan [22].

Table 3 depicts the mineral compositions of wheat flour, un-defatted and defatted jack bean flour in mg/100g. Wheat flour had the highest calcium content (28.60 mg/ 100g). Un-defatted and defatted jack bean flour (0.03 mg/100g), these values are similar to 3.21 g/100g obtained in Canavalia ensiformis seed flour [23]. Interestingly, the value of un-defatted (2.88 mg/ 100g) and defatted (2.74 mg/100g) jack bean flour have higher levels of iron compared to 0.03-0.06 mg/100g values of cowpea (Igna unguiculata l. walp) by [24]. Un-defatted jack bean flour continued the highest level of zinc (4.22 mg/100g) followed by defatted jack bean flour (4.03 mg/100g). This is much higher than 2.90 g/100g by [23], in nutritional Evaluation of Canavalia ensiformis Seed.

-

Table 3:

Mineral composition of wheat flour, defatted jackbean flour and un-defatted jackbean flour.

Magnesium is an essential component of Chlorophyll in green plants and oxidation of enzymes in animals. Un-defatted and defatted jack bean flour had 0.37 mg/100g and 0.35 mg/100g, respectively. The daily requirement of phosphorus for an adult male (67-70 kg body weight) and female (58 kg body weight) is 800mg Adebayo et al. 2007.

There were significant (p<0.05) differences among the shortbread biscuit produced from substituted fermented jackbean flour. The moisture content of the flour samples ranged from 6.85 to 8.77 %. These values are below the minimum limit of moisture content for flour [25]. The values obtained in this study are comparably low, hence, susceptible to microbial attack and has high shelf stability if packaged in moisture-proof containers. The protein content of the flour samples ranged from 8.41 to 10.17 %. The highest value of protein content (10.17 %) was observed in sample C (20 % fermented jackbean flour-substituted cookies) followed by sample B (8.58 %), and while lowest value (8.41 %) was reported in sample A (100% wheat flour). Increase in protein content with increasing fermented jackbean flour substitution level is an indication that jackbean (Canavalia ensiformis) is rich in protein like other leguminous plants. This was similar to the result of [26], that reported an increase in protein levels in biscuits substituted with cowpea (Vigna unguiculata) and Jackbean (canvalia nsiformis) respectively. These processed fermented jackbean flour can be useful to modify the gluten content of wheat flour. This can help to produce biscuit with low gluten content which may be beneficial to people suffering from some coeliac diseases. The increase in protein value of the shortbread biscuit indicated high nutritional value. The crude fibre in the control sample (2.41 %) was higher than sample B (2.37 %) and sample C (1.58 %). This was attributed to the high fibre content of wheat flour.

The fat content of biscuits varied significantly (p < 0.05) and it ranged from 18.39 to 19.42 %. The increase in fat content with increase in the substitution level of fermented jackbean flour for shortbread biscuit could be due to high oil absorption capacity of jackbean (Canavalia ensiformis) in comparison with wheat flour. The ash content of biscuits increased as the substitution level increased and it was the highest (2.11 %) at 20% substitution level. The observed decrease in carbohydrate content of shortbread biscuit with increase in substitution level could be due to the low content of carbohydrate in fermented jackbean. The control sample, however, had the highest carbohydrates content (61.51%). [27], reported that using whole grain raw materials and combining wheat flour with certain legumes and pseudocereals in biscuit production, resulted in improved nutritional and functional properties of the final product (Table 4).

-

Table 4:

Proximate composition of shortbread biscuit samples prepared with different levels of substituted fermented jackbean flour.

The calcium content obtained for shortbread biscuit ranged between 0.11 and 10.58 mg/100g. Sample A (100 % wheat flour) has the highest value for calcium, this may be as a result of high values of calcium (28.60 mg/100g) in wheat flour, observed in this study. The phosphorus content obtained for the shortbread biscuit ranged from 5.90 mg/100g to 6.38 mg/100g. The phosphorus contents increased as the level of incorporation of fermented jack bean flour increased. Phosphorus is required for maintaining body functions and production of energy. It works alongside with calcium to maintain healthy teeth and bones [28]. Consumption of shortbread biscuit fortified with fermented jack bean flour of cookies will provide about 5% of RDA for phosphorus (3500mg).

The iron content of the shortbread biscuit ranged from 1.14 to 2.29 mg/100g. There were significant (p<0.05) differences between the samples. The iron contents of the shortbread biscuit increased with increasing addition of fermented jackbean flour. Hence, reduction in the anti-nutritional factor. The Zinc content ranged from 0.04 to 2.59 mg/100g. The lowest values were found in the sample A (100 % wheat flour). The high value of zinc in sample B and C may be attributed to high mineral content in jackbean, present in all the samples except the control sample. It was generally observed that all the mineral contents were higher in the substituted shortbread biscuit than in the control.

Physical properties of shortbread biscuit samples

The physical properties (spread factor, spread ratio and bulk density) of shortbread biscuit are shown in table 5. Results of these studies indicated that there is significant difference (p < 0.05) between shortbread biscuit fortified with fermented jackbean flour containing with control. The spread factor of sample A(100 % wheat flour) and sample C (20% substitution) were not significantly (p>0.05)different, sample B (10 % substitution) had the least value of 4.43 mm. since the spreadfactor of shortbread biscuit substituted with fermented jackbean flour up to 20% was comparable as that of control sample, the substitution level was considered insignificant.

-

Table 5:

Mineral composition for shortbread biscuit samples prepared with levels of substituted fermented jackbean flour.

Sample C (20 % fermented jackbean flour) had higher value of spread ratio (6.62 mm) than control (6.02 mm). The value observed from this study is similar to the findings of Ho and [29] who reported that the spread ratio of cookies produced from refined flour substituted with blends of pitaya peel flour has a spread ratio of (5.90-6.00 mm). According to [30], cookie spread rate appears to be controlled by dough viscosity; dough with low viscosity causes cookies to spread at fast rate and vice versa. The fermented jackbean flour could have contributed to the modification of the wheat flour. Bulk density of the shortbread biscuit were not significantly (p>0.05) different (Table 6).

-

Table 6:

Physical properties of shortbread biscuit samples prepared with different levels of substituted fermented jackbean flour.

Sensory evaluation of shortbread biscuit samples

The sensory scores of the shortbread was presented in table 7. Shortbread biscuits prepared from 10 % substituted fermented jackbean flour were rated high in colour, flavour, mouthfeel and overall acceptability with significant difference (p<0.05) as compared to control. Thus, substituting part of wheat flour with fermented jackbean seed flour did not impair sensory quality of biscuits. Therefore, jackbean flour has potential use in biscuit production. The present obtained results are similar to that reported by [31], who noted that partially replacing wheat flour with cassava flour up to 15% did not alter the composite cookies acceptability.

-

Table 7:

Sensory sores of shortbread biscuit samples prepared with different levels of substituted fermented jackbean flour.

Conclusion

The inclusion of fermented jackbean flour to whet flour greatly increased the proximate, mineral, physical and sensory property of the flour and product. Jackbean fermentation increases nutrient bioavailability of the whole food materials. Shortbread biscuits prepared from 20 % substitution of fermented jackbean flour was comparably with the control samples in terms of the physical characteristics. Sensory scores also showed that sample B (90% wheat flour and 10% fermented jackbean flour)was preferred with reference to colour, flavor, mouth-feel and overall acceptability. Consumption of shortbread biscuit fortified with fermented jackbean flour at 10 % and 20 % levels may therefore be encouraged, thus could be used as a nutritious food for children and adolescent in developing countries.

- Hooda S, Jood S (2005) Organoleptic and nutritional evaluation of wheat biscuits supplemented with untreated and treated fenugreek flour. Food Chemistry 90: 427–435. Link: https://goo.gl/DFMXiJ

- Iwegbue CMA (2012) Metal contents in some brands of biscuits consumed in southern Nigeria. American Journal of Food Technology 7: 160-167. Link: https://goo.gl/y4uxc8

- Okpala, L, Okoli, E, Udensi E (2013) Physico-chemical and sensory properties of cookies made from blends of germinated pigeon pea, fermented sorghum, and cocoyam flours. Food Science and Nutrition 1: 8–14. Link: https://goo.gl/cp9oPP

- Baljeet SY, Ritika BY, Reena K (2014) Effect of incorporation of carrot pomace powder and germinated chickpea flour on the quality characteristics of biscuits. International Food Research Journal 21: 217-222. Link: https://goo.gl/NcTtEX

- Udedibe ABI (1990) Nutritional evaluation of Jack bean (Canavalia ensiformis) for the Nigerian Poultry Industry. AMB 1019: 361-365. Link: https://goo.gl/faonxa

- Akpapunam, MA, Sefa-Dedeh S (1997) some physical chemical properties and antinutritional factors of raw, cooked and germinated Jack bean (Canavalia ensiformis). Food Chemistry 59: 121-125. Link: https://goo.gl/JGMTa1

- Udedibie, ABI, Nkwocha, CO (1990) Comparative study of jack bean (C. ensiformis) and sword bean (C. gladiata) as protein supplements for young broiler chicks. Agriculture Journal 24: 7-14.

- Helland MH, Wicklund T Narvhus JA (2002) Effect of germination time on alpha-amylase production and viscosity of maize porridge. Food Research International 35: 315-321. Link: https://goo.gl/ZCczw6

- Ochanda SO, Onyango CA, Mwasaru AM, Ochieng JK, Mathooko FM (2010) Effects of malting and fermentation treatments on group B vitamins of red sorghum, white sorghum and pearl millets in Kenya. Journal of Applied Biosciences 34: 2128-2134. Link: https://goo.gl/EKFmpW

- Hallen E, Ibanoglu S, Ainsworth P (2004) Effect of fermented/germinated cowpea flour addition on the rheological and baking properties of wheat flour. J Food Eng 63: 177–184. Link: https://goo.gl/k2W40

- Chavan JK, Kadam SS (1989) Nutritional improvement of cereals by fermentation. Crit Rev Food Sci Nutr 28: 349–361. Link: https://goo.gl/gcucX1

- AOAC (2010) Official Methods of Analysis 17th edition Association of Official Analytical Chemists Washington DC USA. Link: https://goo.gl/Tj8X2T

- McWatters KH, Ouedraogo JB, Resurrection AVA, Hung YC, Phillips RD (2003) Physical and sensory characteristics of sugar cookies containing mixtures of wheat, fanio (Digitaria exilis) and cowpea (Vigna unguiculata) flours. International Journal of Food Science and Technology 38: 403-410. Link: https://goo.gl/Tj5t7H

- Serrem C, Kock H, Taylor J (2011) Nutritional quality sensory quality and consumer acceptability of sorghum and bread wheat biscuits fortified with defatted soy flour. Int J Food Sci Technol 46: 74-83. Link: https://goo.gl/GDC8Cb

- Islam T, Chowdhury A, Islam M, Islam S (2007) Standardization of Bread Preparation from Soy Flour. Int J Sustain Crop Prod 2: 15-20. Link: https://goo.gl/D67ntB

- Doss A, Pugalenthi M, Vadivel VG, Subhashini G, Anitha Subash R (2011) Effects of processing technique on the nutritional composition and antinutrients content of under–utilized food legume Canavalia ensiformis LDC. International Food Research Journal 18: 965-970. Link: https://goo.gl/bBhX8a

- Bressani R (2002) Factors influencing nutritive value in food grain legumes: Mucuna compared to other grain legumes. In: Proceedings of an International Workshop on: “Food and Feed from Mucuna: Current uses and the way forward” Flores M., Eilitta M., Myhrman R, Careuev LB. and Carsky RJ (Eds.),Tegucigalpa, Honduras 26-29 Link: https://goo.gl/dkebKr

- Sridhar KR, Seena S (2006) Nutritional and antinutritional significance of four unconventional legumes of the genus Canavalia – A comparative study Food Chemistry 99: 267-288. Link: https://goo.gl/w8Pv8f

- Vadivel V, Janardhanan K (2001) Nutritional and antinutritional attributes of the under-utilized legume Cassis floribunda cav Food Chemistry 73 209-215. Link: https://goo.gl/bcXpKk

- Siddhuraju P, Becker K (2001) Species / variety differences in biochemical composition and nutritional value of Indian tribal legumes of the genus Canavalia. Nahrung/Food 45: 224-233. Link: https://goo.gl/FMGmwa

- Pugalenthi M, Vadivel V (2005) Nutritional evaluation and the effect of processing methods on antinutritional factors of sword bean (Canavalai gladiata (Jacq. DC.). Journal of Food Science and Technology 42: 510-516.

- Oshodi AA, Olaofe O, Hall GM (1993) Amino acid fatty acid and mineral composition of Pigeon pea (Cajanus cajan). Inter J Food Sci and Nutri 43: 187-191. Link: https://goo.gl/oi4o7x

- Abitogun AS, Olasehinde EF (2012) Nutritional Evaluation of Seed and Characterization of Crude Jack Bean (Canavalia ensiformis) Oil Journal of Applied Chemistry 1: 36-40. Link: https://goo.gl/1gCFeo

- Famata,AS, Modu S, Mida HM, Hajjagana L, Shettima AY, et al. (2013) Chemical composition and mineral element of two cowpea varieties as food supplement. International Research Journal of Biochemistry and Bioinformatics 3: 93-96. Link: https://goo.gl/SHF2Ss

- Ihekoronye AI, Ngoddy PO (1985) Integrated Food Science and Technology for the Tropics. 2nd ed. Macmillan Publishers Ltd. London. Link: https://goo.gl/WDgEYn

- Alobo AP (2007) Effect of Jackbean (Canavalia ensiformis) Flour on Maize Cookie Characteristics. Proceeding of Nigerian Institute of Food Science and Technology 2007: 189-190.

- Vitali D, Dragojevic V, Sebecic B (2009) Effects of incorporation of integral raw materials and dietary fibre on the selected nutritional and functional properties of biscuits. Food Chem 114: 1462-1469. Link: https://goo.gl/vXwLcG

- FAB (2012) Vitamins and other Mineralshttp://www.fabflour.co.uk/content/1/256/ vitamins-and-other-minerals.html. accessed on.

- Ho L, Abdul Latif NW (2016) Nutritional composition, physical properties, and sensory evaluation of cookies prepared from wheat flour and pitaya (Hylocereus undatus) peel flour blends. Cogent Food & Agriculture 2: 1136369 Link: https://goo.gl/LfSkcB

- Hoseney RC, Rogers DE (1994) Mechanism of sugar functionality in cookies. In H Faridi (Ed.) The science of cookie and cracker production (pp. 203–226). New York, NY: Chapman & Hall.

- Ubbor SC, Akobundu ENT (2009) Quality characteristics of cookies from composite flours of watermelon seed, cassava and wheat. Pakistan Journal of Nutrition 8: 1097–1102. Link: https://goo.gl/3itHTx

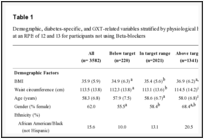

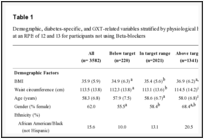

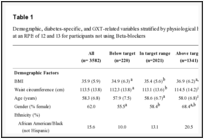

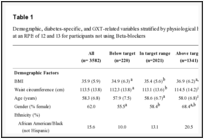

Table 1:

Shortbread Blend formulations.

Flour blend for

shortbread biscuit

Wheat flour

Fermented jackbean

flour (g)

SBA

100

0

SBB

90

10

SBC

80

20