Authors:

Addisu Bihonegn1*, Desalegn Begna2, Asaminew Tassew3 and Zeleke Mekuriaw4

1Apiculture and Sericulture Research Case Team, Sekota Dry land Agricultural Research Center, Sekota, Ethiopia

2Holeta Bee Research Center, Holeta, Ethiopia

3Department of Animal Production and Technology, College of Agriculture and Environmental Sciences, Bahir Dar University, Bahir Dar, Ethiopia

4Livestock and Irrigation Value Chains for Ethiopian Smallholders Project, International Livestock Research Institute, Ethiopia

Received: 07 August, 2017; Accepted: 14 September, 2017; Published: 15 September, 2017

Addisu Bihonegn, Apiculture and Sericulture Research Case Team, Sekota Dry land Agricultural Research Center, Sekota, Ethiopia. E-mail:

Bihonegn A, Begna D, Tassew A, Mekuriaw Z (2017) Physicochemical properties of Ethiopian Beeswax, the case of South Wollo zone, Amhara Region. Int J Agric Sc Food Technol 3(3): 061-066. DOI: 10.17352/2455-815X.000024

© 2017 Bihonegn A, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Adulteration; Beeswax; Physicochemical; Quality; South wollo

The study was conducted in three purposively selected districts of South Wollo Zone, Tehulederie, Kalu and Dessie Zuria, intended to analyze the physicochemical properties of beeswax produced in 2015/6. Twenty-six beeswax samples were collected being sourced from honey extract, ‘Tej sefef’, old combs and purchased beeswax blocks and analyzed at Sekota Dry land Agricultural Research Center laboratory according to the standard protocols of Ethiopian Beeswax specification ET-1203-2005 developed by Quality Standard Authority of Ethiopia in 2005. The laboratory result showed that the compositional content of beeswax collected from the study areas falls within the range of good quality parameters set for national and world standards. Except for ash content, there is no significant compositional content variation (P>0.05) between the sampled districts. However, there is significant variation (P<0.05) between beeswax samples based on the source from which they were obtained. The mean values are specific gravity (0.9552±0.0034), melting point (61.5628±1.50080C), refractive index (1.4439±0.0004), ash content (0.0345±0.0429%), total volatile matter (0.5491±0.2488%), acid value (18.9155±2.7735), saponification value (91.1901±22.3015), ester value (72.0619±20.2859), and ester to acid ratio (3.7211±0.8569). However, melting point, saponification value, ester value and ester to acid ratio values of purchased beeswax samples and beeswax samples from old combs of absconded colonies showed lower result than the national and international limit. In general, this study identified physicochemical properties of the beeswax in the study areas and contributed to the information on beeswax quality of Ethiopia suggesting legal intervention on controlling purchasing of beeswax in bulk

Introduction

Ethiopia is a home of diversified fauna and flora, which favor the existence of a number of bee colonies and bee subspecies. In Ethiopia, about 1.9 million farm households are involved in beekeeping and there are about 10 million colonies out of which about 5.92 million are hived [1], and it is estimated that the country has the potential to produce 500,000 tons of honey and 50,000 tons of beeswax per annum. However, currently the country produces 50,790.58 tons of honey in 2015/6 [1], and about 5,344 tons of beeswax in 2013 [2]. This shows that the country is still producing only about 10% of its potential. Beeswax is one of the most valuable and oldest bee products primarily used to construct foundations in beekeeping [3,4]. Besides, humankind is still using it in various fields such as cosmetics, foods, pharmaceuticals, engineering and industry [5]. The quality of beeswax is one of the main concerns of apiarists and a determinant factor in the beekeeping development. Generally, beeswax product quality has always been low, leading to high domestic utilization and low export earnings. Besides, due to its high demand in the global market, adulteration of beeswax with cheaper materials and lack of traceability turn out to be common challenges in beeswax quality [6]. On the other hand, due to prolonged over heating throughout rendering, there has been report of quality deterioration and compositional alteration of natural beeswax [7]. Hence, the beekeepers in particular and the country, in general, were not benefiting from the sector. For that reason, to take the advantage of opportunities from beeswax, interventions to verify the quality of beeswax produced are very crucial. Beeswax is a natural product, no additives are permitted, and it needs no longer heating or higher temperatures that lead to greater degradation and loss of esters. Beeswax is an extremely complex material containing over 300 different substances [8]. It consists mainly of esters of higher fatty acids and alcohols and small quantities of hydrocarbons, acids and other substances. In addition, approx. 50 aroma components have been identified. Currently, adulteration and contamination are main quality issues [9]. Quality control of beeswax is important to determine its suitability for processing and to meet the market demand. Examination of the sensory characteristics (e.g. odor and color) of beeswax allows a simple and quick quality check but this does not guarantee that the beeswax has not been adulterated. Thus, determination of physicochemical characteristics at laboratory is significant in this regard. Therefore, with this rationale, this study was designed to analyze the physicochemical properties of beeswax produced in the study area with the purpose of confirmation against physicochemical indicators of national and international standards.

Material and Methods

Description of the study area

South Wollo zone is one of the 11 zones of Amhara region, having an area of 17,067.45km2[10], located 10.200 - 11.710 N and 38.410 - 40.020 E North of Ethiopia [11], whose main capital is Dessie town. The zone consists of 20 districts from which the three districts namely, Tehulederie (midland), Kalu (lowland) and Dessie Zuria (highland) purposively selected for this study based on the beekeeping potential, accessibility and their proximity to honey and beeswax marketing and processing routs. The zone has a long-term mean (1162mm) rainfall per annum. The monthly minimum and maximum temperature is 12.60C and 26.40C respectively.

Beeswax Sample Collection and Preparation

Twenty-six beeswax samples were collected from three agro-ecologically different districts (Tehulederie, Kalu and Dessie zuria) from December 2015 to March 2016. The collected beeswax samples were extracted from honey purchased from beekeepers and local market, old combs collected from absconded colonies, ‘Tej sefef’ purchased from local honey mead houses and beeswax blocks purchased from verandah. Crude beeswax samples of 1kg were made from each source. Before physical and chemical analysis, all beeswax samples were rendered, refined and purified. Physical and chemical analysis was done at Sekota Dry land Agricultural Research Center laboratory following the protocols of the Ethiopian Beeswax Specification ET-1203-2005[12]. All chemicals and reagents used were analytical grade.

Specific gravity at 200C

Approximately 2g of the beeswax sample melted in a porcelain crucible at a temperature of about 1000C and allowed to cool to room temperature. The sample weighed suspended with a tarred thread after it was stored for 2 hours at a temperature of 20 ±10C. The mass of the sample was determined, first in air and then in rectified spirit maintained at 20±10C. The specific gravity at 200C/200C of the rectified spirit was measured by means of the specific gravity bottle to determine the specific gravity of the beeswax sample.

Specific gravity at 200C /200CWhere,

M1 mass in gram of the material in air.

d specific gravity of rectified spirit.

M2 mass in gram of the material in alcohol.

Melting point, 0C

The melting point is an important physical property of beeswax used to identify as an indication of its purity. The melting point of solid is defined as the temperature at which the solid exists in equilibrium with its liquid under an external pressure of one atmosphere [9]. The beeswax sample was melted and a capillary tube was dipped into melted beeswax and let stay for 24 hours. The capillary tube inserted into melting point apparatus (with digital thermometer indicator, model LMP-11). After the sample has attained the melting temperature, the melting point read and recorded. Each beeswax sample was analyzed in triplicate.

Refractive index at 750C

The refractive index determination is a method to measure the ratio of the velocity of light in air to that in the sample. Bench top digital ATAGO® Abbe refractometer was used to measure refractive index. The sample melted and filtered through fast filter paper to remove any impurities and last traces of moisture. The temperature of the refractometer was adjusted at 75±10C by circulating water from the water bath. Few drops of the sample were placed on the lower prism and the prism closed tightened firmly allowed to stand for one to two minutes. After the sample has attained the test temperature, the reading of refractive index of the sample recorded.

Ash content, % by mass, max

The platinum dish was heated to redness, cooled to room temperature in a desiccator and weighed. About 50g of the material was taken in a watch-glass and weighed accurately. About three-quarter of this quantity was transferred to the platinum dish and heated on a hot plate so that the material burns gently at the surface. When about half of the material is burnt away, heating stopped, cooled and the remainder of the material was added. The dish heated again as before, until the material completely charred. After that, the material was incinerated in a muffle furnace at 550°C to 650°C for 1 hour, cooled to room temperature in desiccators and weighed. Incineration, cooling and weighing were repeated until the difference between two successive weighing was less than one milligram. The ash content of the sample calculated with the following formula.

Ash, percent by mass =

Where,

M2= mass in g of the ash, and

Ml = mass in g of the material taken for the test.

Total volatile matter, % by mass, max

About 10g of the material was weighed accurately in a suitable dish, previously dried and weighed, and placed in an oven maintained at 105 20C for 6 hours. After 6 hours, the dish was cooled in a desiccator and weighed. The dish heated again in the oven for 30 minutes. The process repeated until the loss in mass between two successive weighing was less than one milligram. The lowest mass obtained was the record as the total volatile matter of the sample taken with the following formula.

Total volatile matter at 1050C percent by mass =

Where,

M1 mass in gram of the dish with the material before heating

M2 mass in gram of the dish after heating

M3 mass in gram of the empty dish

Acid value, max

The material was mixed to make entirely liquid and accurately about 5 g of the material was weighed in a 250-m1 conical flask. 75 ml of a mixture of two parts of benzene and one part of rectified spirit was added. The sample was heated under reflux until it dissolved, allowed to cool to room temperature and titrated with standard potassium hydroxide solution using phenolphthalein as indicator until pink color is observed. The acid value (in mg KOH/g) was calculated by the following formula.

Acid value =

Where, 56.1 is equivalent weight of KOH

V volume in ml of standard potassium hydroxide solution used,

N normality of standard potassium hydroxide solution, and M mass in gram of the material taken for the test.

Saponification cloud value, min

The saponification value is the number of milligrams of potassium hydroxide required to hydrolyze 1g of sample beeswax. Determining the saponification cloud point is an easy, sensitive and best method for determining adulteration of beeswax. However, the method is limited to detecting quantities greater than 1% of high melting point (80-85 °C) paraffin waxes, or more than 4-5 % of low melting (50-55°C) paraffin [9].

Accurately about 2g of beeswax was weighed in a tarred conical flask, 25 ml of methyl ethyl ketone added, followed by 25 ml of alcoholic potassium hydroxide solution. Few pieces of pumice stone were added and the reflux condenser was connected to the flask. The flask heated on a water-bath or electric hot plate for about 2 hours to boil steadily but gently. The inside of the condenser washed down with about 10 ml of rectified spirit after the flask and condenser have cooled. 1 ml of phenolphthalein was added and the residual potassium hydroxide was titrated with 0.5 M standard hydrochloric acid. A blank assay or titration was also performed with 25 ml of 0.5 M alcoholic potassium hydroxide. The following formula was used to determine the Saponification Value according to Ethiopian Beeswax Specification ET-1203-2005 of Quality Standard Authority of Ethiopia.

Saponification cloud value =

Where, B = volume in ml of standard hydrochloric acid required for the blank,

S = volume in ml of standard hydrochloric acid required for the material,

N =normality of standard hydrochloric acid, and

M = mass in g of the material taken for the test

Ester value

The ester value calculated as the acid value determined subtracted from the saponification value.

Ester value = Saponification value - Acid value

Ester to acid ratio

The ester to acid ratio calculated by dividing the ester value to the acid value.

Ratio number =

Data management and Statistical Analysis

The obtained data were analyzed using SAS software version 9.0. Whenever ANOVA showed statistically significant difference, Generalized Linear Model at P<0.05 level was used to separate the means. The following analysis of variance model was used for data analysis.

Yij=µ + αi+ Єij

Where: Yij = quality of beeswax

µ = overall mean

αij = the effect of the ith location

Єij = random error

Results and Discussion

Specific gravity at 200C

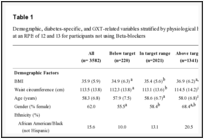

The specific gravity of sample collected from the study areas ranges from 0.9485 to 0.9624 with a mean value of 0.9552 (Table 2) and this result concur with result of [13], that reported 0.9598 for Bale beeswax (south-eastern Ethiopia). Whereas, [14], reported lower specific gravity for beeswax samples from honey extract (0.9497) but with similar findings for beeswax from ‘Tej sefef’ (0.9619). The specific gravity of samples collected from old combs (0.9514) and purchased beeswax blocks (0.9534) was significantly lower (P<0.05) than the specific gravity of beeswax samples extracted from honey (0.9565) and ‘‘Tej sefef’ (0.9566) (Table 2) suggesting that specific gravity of beeswax influenced by its origin[14]. However, there was no significant difference (P>0.05) between beeswax samples collected from the three districts of the study areas (Table 1). The present beeswax specific gravity analysis result met the national and international standards (Table 2).

-

Table 2:

Physicochemical properties of beeswax quality and the comparison of mean results with National and International standards (N=26).

Melting point, 0C

The average melting point of each beeswax sample from the study area recorded as 61.560C ranging from 58.3 to 68.50C (Table 2). The test results of beeswax melting point indicated no significant difference (P>0.05) between the samples collected from the three districts of the study areas (Table 1). Likewise, there was no significant difference (P>0.05) between the samples obtained from the four sources from which the beeswax sample was taken (Table 2). This suggests that geographical difference and source cannot influence melting point of beeswax. Though, the result showed no statistical difference among the beeswax collected from four sources (Table 2), the purchased and old combs sourced beeswax samples demonstrated lower melting point of 60.43oC (ranging from 58.330C to 64.50C) and 60.60C (ranging from 59.30C to 62.00C) respectively (Table 2) and these results do not meet the national and international standards (61-65oC). The melting points of beeswax gradually decline with increased proportion of adulteration with cheaper materials like animal tallow [4]. However, the overall mean melting point of the examined samples (61.560C) was within the acceptable range of Ethiopian and European standards. [4, 13], reported acceptable mean beeswax melting point of 62.50C and 62.390C respectively.

Refractive index, at 750C

The mean refractive index of beeswax samples collected from the study areas was 1.4439 at 750C (Table 1) and this agree with finding of [13], that reported similar figure of refractive index (1.4426). According to the test results for beeswax collected from different localities, there was no significant difference (P>0.05) between districts (Table 1). However, there was significantly (P<0.05) lower refractive index (1.4434) for beeswax obtained from old combs than beeswax from ‘‘Tej sefef’ (1.4440) and honey extract (1.4440) (Table 2). Generally, the current study indicated that the result was within the limits of Ethiopian and International quality standards, (Table 2) showing it was free of contamination.

Ash content, % by mass, max

Ash content determination of beeswax is important because it represents its mineral content [14]. The mean value for ash content of current study result (0.0345%) is lower than the maximum limit set by the Ethiopian standard (0.2% by mass) fulfilling the national requirement [12]. This implies that, on the other hand, there was a significant difference (P<0.05) in ash content between beeswax from Tehulederie (0.5794) and Dessie Zuria (0.0173) (Table 1) signifying that mineral content of beeswax differ by its geographical origin. Moreover, the test results of beeswax samples obtained from different sources indicated significant difference (P<0.05) in ash content between old combs (0.0853), purchased beeswax block (0.0110) and honey extract (0.0213) (Table 2). The higher ash content in old combs might be due to the higher accumulation of minerals because of repeated brood rearing (aging) and there is a finding that shows mineral element traces in honey and wax were significantly correlated with comb age [16]. Similarly, [14] reported ash content of 0.0367 and 0.0267 for honey extracted beeswax and ‘Tej sefef’ respectively.

Total volatile matter, % by mass, max

In beeswax, volatile matters are those substances, other than moisture, that is given off as gas and vapor during combustion in the dry oven out of air contact. The total volatile matter of the collected beeswax samples ranged from 0.2331 to 1.2450% with the mean value of 0.5491% (Table 2) and (Tesfaye et al., 2016) reported comparable result (0.3335%). The beeswax from ‘Tej sefef’ (0.8077) was significantly higher (P<0.05) than the purchased beeswax blocks (0.3101), old combs (0.5246) and honey extract (0.5491) (Table 2). However, the result indicated no significant difference (P>0.05) in total volatile matter among the samples collected from the three districts of the study areas (Table 1). The mean result fulfills the national standard, 0.75% (Table 2) and Tanzanian standard, 1% [17], suggesting that the beeswax produced in South Wollo zone is of required quality.

Acid value, max, (mgKOH/g)

The acid value is the number of milligrams of potassium hydroxide (KOH) required to neutralize the free acids in 1 g of sample. The test result of beeswax acid value ranged from 14.4648 - 23.4238 with the mean value of 18.9155 (Table 2) that fall within the range of national and international requirements, 17-24 mgKHO/g (Table 2), suggesting beeswax from the study areas is more or less natural with no/fewer contaminants. Also (Adgaba, 2007) and (Tesfaye et al., 2016) reported an acceptable mean acid value of 21.66 and 22.33 of Ethiopian beeswax respectively. According to this study result, There is no significant difference (P>0.05) in acid value among the samples collected from the three districts of the study areas (Table 1) and between beeswax collected from different sources (Table 2).

Saponification cloud value, min, (mgKOH/g)

According to this study, the mean saponification cloud value of the collected beeswax sample ranged from 48.7972 to 123.4015 with the mean value of 91.1901mgKOH/g (Table 2) and this result agree with [13] that reported an acceptable saponification value of 98.04. The mean saponification value of the study districts was within the national and international standards (Table 2). The result indicated no significant difference (P>0.05) in saponification value among the samples collected from the three districts of the study areas (Table 1) and the four sources of beeswax samples (Table 2). Regardless of statistical non-significance, the mean values of the purchased beeswax blocks (74.6544±22.7111) and old combs (76.3537±21.4929) did not fulfill the required minimum beeswax saponification value 85-105 [12], suggesting low quality due to foreign materials without indicating its type and amount.

Ester value (mgKOH/g)

The ester value is the number of milligrams of potassium hydroxide (KOH) required to saponify the esters in 1g of sample and determined by the difference of saponification value from acid value. According to this study, the mean result of ester value in mgKOH/g is 72.0619±20.2859 ranging from 33.7414 - 100.6548 (Table 2). In addition, [12, 4] reported mean ester value of 75.58 and 77.89 for three districts of Bale zone, and Holleta Bee Research Center, respectively. The current test result indicated no significant difference (P>0.05) in ester value among the samples collected from the three districts of the study areas (Table 2). However, the average ester value of beeswax collected from Tehulederie district (67.6877±22.2238) was lower than the lower limit of national and international requirements (70-80). On the other hand, the ester values of the purchased beeswax (52.9687) and old combs (55.4867) showed lower value as compared to the required national and international limit, indicating that beeswax from these sources contains less amount of saponifiable matter. Generally, the overall mean ester value result of the current study meets the quality standard limits of national and international (Table 2).

Ester to acid ratio

The ratio of ester values to acids, a parameter determined in the pharmacopoeia gives information whether pure natural beeswax is changed significantly by prolonged or excessive heating leading to greater degradation and loss of esters [7]. According to this study, the mean value of ester to acid was 3.7211 ranging from 2.1328 - 4.9360 (Table 2) and this result agree with [4, 12] that reported ester to acid ratio of 3.64 and 3.38 for Holeta and Bale natural forest respectively. The eater to acid ratio of beeswax samples collected from honey extract (4.0615) was significantly (P<0.05) higher than that of purchased beeswax block samples (2.7035) (Table 2) suggesting beeswax is changed significantly by prolonged or excessive heating. This is because longer heating or higher temperatures lead to greater degradation and loss of esters (Bogdanov, 2016). The result indicated no significant difference (P>0.05) among the samples collected from the three districts of the study areas (Table 1). The mean result falls within the range of Kenyan standard, 3.0-4.3 [18].

Conclusions and Recommendations

Based on this study findings, the overall mean values of the compositional content of beeswax in the study areas falls in the range of good quality compared to national and world standards set for beeswax quality determination. Furthermore, the study identified beeswax samples which were obtained through purchase as blocks from city markets as having lower melting point, saponification, ester and ester to acid ratio values suggesting lower quality due to existence of foreign materials. This study identified the physicochemical properties of beeswax in South Wollo zone of Amhara region and contributed to increased knowledge keeps all the stakeholders vigilant on its development, quality and market.

Acknowledgements

The authors would like to acknowledge Sekota Dry land Agricultural Research Center and its staffs for material support and laboratory analysis. In addition, we would like to thank Livestock and Irrigation Value Chains for Ethiopian Smallholders (LIVES) project for financial support.

- CSA (2016) Agricultural Sample Survey 2015/16 [ 2008 E.C.] volume II: Report on Livestock and Livestock Characteristics (Private Peasant Holdings). STATISTICAL BULLETIN 583 (Vol. II). Addis Ababa, Ethiopia: Federal Democratic Republic of Ethiopia Central Statistical Agency (CSA). Link: https://goo.gl/Bp1rTW

- FAOSTAT (2016) FAOSTAT data. Statistical Database. Livestock Primary. Link: https://goo.gl/g756FA

- Ayalew Kassaye (2008) Honey and Beeswax Value Chain of BOAM Programme. Establishment of Apiculture Data Base in Ethiopia. SNV Netherlands Development Organization. Addis Ababa, Ethiopia. Link: https://goo.gl/HmSfrc

- Nuru Adgaba (2007) Physical and Chemical Properties of Ethiopian Beeswax and Detection of Adulteration. Ethiopian Journal of Animal Production (EJAP) 7: 39. Link: https://goo.gl/tDeyo7

- Hossain ME, Rahman MS, Ketata C, Islam MR (2009) Molecular Structure Evaluation of Beeswax and Paraffin Wax by Solid-State 13C CP/MAS NMR. Journal of Manipulative and Physiological Therapeutics 35: 692–700. Link: https://goo.gl/TJaKmM

- Gemechis Legesse Yadeta (2014) Beeswax Production and Marketing in Ethiopia: Challenges in Value Chain. Agriculture, Forestry and Fisheries 3: 447–451. Link: https://goo.gl/SXT3Et

- Bogdanov S (2009) Beeswax: Production, Properties Composition and Control. In The Beeswax Book 1–17. Link:

- Bogdanov S (2016) Beeswax: Composition and Control. In Beeswax Book Retrieved from 1–18. Link: https://goo.gl/JHxXbJ

- Bonvehi JS, Bermejo FJO (2012) Detection of adulterated commercial Spanish beeswax. Food Chemistry 132: 642–648. Link: https://goo.gl/H8d9CP

- Google Map (2016) South Wello - Google Maps. Link: https://goo.gl/dpGAer

- QSAE (2005) Quality and Standards Authority of Ethiopia. Ethiopian Standard, Beeswax-Specification; ES 1203: 2005. Link: https://goo.gl/RY42bM

- Bekele Tesfaye, Desalegn Begna, Mitiku Eshetu (2016) Analysis of Physico-Chemical Properties of Beeswax Produced in Bale Natural Forest, South-Eastern Ethiopia. European Journal of Biophysics. Special Issue: Environmental Toxicology 4: 42–46. Link: https://goo.gl/sb1jdB

- Solomon Getachew (2007) Evaluation of Imported and Local Wax for Cheese Processing. Addis Ababa University, Technology Faculty, Chemical Engineering Department Food Engineering Program, Addis Ababa, Ethiopia.Master of Engineering in Food Engineering Thesis. Link: https://goo.gl/fySN69

- Nyau V, Mwanza E, Moonga H (2013) Physico-chemical qualities of honey harvested from different beehive types in Zambia. African Journal of Food, Agriculture, Nutrition and Development 13: 7415–7427. Link: https://goo.gl/a3RyHG

- Taha EKA, Manosur HM, Shawer MB (2010) The relationship between comb age and the amounts of mineral elements in honey and wax. Journal of Apiculture Research and Bee World 49: 202–207. Link: https://goo.gl/Efqcwe

- Kenya Bureau of Standards (2013) Specification for Natural Beeswax. Kenya Standard. CD/05-1279:2013. Link: https://goo.gl/ypSfLM

- Tanzania Bureau of Standards (2010) Tanzania Standard Beeswax Specification. TBS/ AFDC 17: 1–11. Link: https://goo.gl/a9QqoL

- Wikipedia.org. (2015) List of districts in the Amhara Region - Wikipedia, the free encyclopedia. Link: https://goo.gl/rKx49x

Table 1:

Physicochemical properties of beeswax samples collected from the study districts (N=26).

Characteristics

Districts (Mean ±SD)

Overall

(N=26)

Tehulederie

(N=10)

Kalu

(N=7)

Dessie Zuria

(N=9)

Specific gravity

0.9548±0.0048

0.9551±0.0031

0.9557±0.0015

0.9552±0.0034NS

Melting point (0c)

61.9350±1.6466

60.8905±1.6730

61.7622±1.1435

61.5628±1.5008NS

Refractive Index

1.4438±0.0005

1.4439±0.0004

1.4439±0.0003

1.4439±0.0004NS

Ash content

0.5794±0.0616a

0.0209±0.0153ab

0.0173±0.0062b

0.0345±0.0429

Total Volatile Matter

0.5792±0.1802

0.6361±0.3416

0.4479±0.2238

0.5491±0.2488NS

Acid Value

19.2516±2.6714

18.8792±2.8757

19.6210±2.3452

18.9155±2.7735NS

Saponification Value

86.4938±25.1332

91.7174±26.4019

95.9998±16.3397

91.1901±22.3015NS

Ester value

67.6877±22.2238

72.2063±24.5444

76.8097±15.1407

72.2746±20.4608NS

Ester to Acid Ratio

3.5152±0.7965

3.6321±0.9994

4.0192±0.8198

3.7995±0.9936NS